This 12 months, world EV gross sales are anticipated to leap nearly 25% in contrast with 2024. Because the demand for electrical autos soars, there’s a looming concern for trade consultants: determining the easiest way to repurpose the several-hundred-pound batteries that energy these autos.

In accordance with a 2023 research by McKinsey, the worldwide provide of EV batteries for recycling is steadily rising and is predicted to hit a whopping 7,850 kilotons in 2035. That very same 12 months, McKinsey tasks that EV battery recycling might be a $7.2 billion trade within the U.S. At the moment, although, consultants are nonetheless looking for the easiest way to truly scale the recycling course of. The prevailing technique is a method that primarily entails shredding EV batteries right into a superfine powder—a course of that has proved pricey, difficult, and inefficient.

Now, researchers on the Massachusetts Institute of Expertise have revealed a research exhibiting a brand new technique to probably bypass the shredding step altogether. In accordance with Yukio Cho, lead creator on the research and a Stanford vitality postdoctoral fellow, the workforce has developed a brand new technique to construct a battery that makes it a lot simpler to separate its element elements, leaving them prepared for recycling.

The present state of EV recycling

The 2 principal ways in which EV batteries are diverted away from landfills are by way of reuse and recycling. Some firms are discovering methods to repurpose EV batteries after they’re now not match for driving. One startup is utilizing retired EV batteries to energy up a complete knowledge heart in Nevada, for instance, whereas one other is repurposing outdated batteries to run new EV charging stations.

Others are trying to find methods to interrupt these batteries down and reuse their worthwhile parts. The present trade customary is to shred the batteries right into a fantastic powder known as “black mass,” which must be sorted into salvageable metallic elements. The sorting course of is messy, difficult, and sometimes requires specialised amenities in superior recycling markets like China to truly make the metals usable. Even then, Cho says, the acids used to kind out the metals can pose an environmental threat—and, to prime all of it off, the entire course of is pricey.

“Elemental parts are so difficult,” Cho says. “When you’ve generated this black mass, it’s actually tough to make recovering the important supplies cost-positive.”

Cho says there’s not a lot consensus amongst consultants immediately on what number of EV batteries are literally getting recycled and what number of are being diverted to landfills. What is evident, although, is that there’s loads of motivation to show EV manufacturing right into a extra round economic system. To begin, siphoning e-waste into trash heaps poses the chance of leaching hazardous supplies into soil and water. From an financial perspective, EV batteries additionally comprise worthwhile metals like nickel, cobalt, manganese, and lithium, which will be harvested and reused to stop costlier and polluting ore-mining operations.

Think about an EV battery like a ham sandwich

To skirt across the difficulty of black mass totally, Cho and his workforce determined to take a completely novel method to EV battery design.

“Thus far within the battery trade, we’ve centered on high-performing supplies and designs, and solely later tried to determine how one can recycle batteries made with complicated constructions and hard-to-recycle supplies,” Cho informed MIT Information in an interview. “Our method is to begin with simply recyclable supplies and work out how one can make them battery-compatible.”

A rendering reveals (left) the mPEGAA molecule designed by researchers, (center) how the molecules self-assemble into nanoribbons, and (proper) how the molecules are used for the battery electrolyte. [Image: courtesy of the researchers]

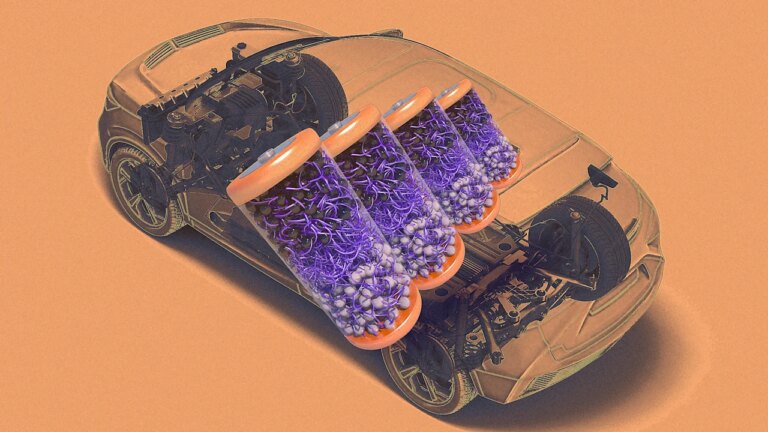

EV batteries are made from three principal elements: the positively charged cathode, the negatively charged electrode, and the electrolyte that shuttles lithium ions between them. Sometimes, EV batteries are sealed so tightly that, in an effort to take them aside effectively, shredding them turns into the easiest way to recycle them. The novel innovation from the MIT workforce is a brand new electrolyte materials which, when soaked in an natural solvent, “simply dissolves like cotton sweet,” simply separating the batteries’ elements.

Cho compares the innovation to a hypothetical ham sandwich. Think about that the sandwich has been glued shut, and in an effort to retrieve the bread, lettuce, and ham, it has been shredded and have to be sorted by minute particles. Now, think about that the sandwich was held collectively by mayo as a substitute: You may simply separate all the sandwiches’ parts. That’s primarily the distinction between the black mass recycling step and the electrolyte course of that his workforce is engaged on.

Cho’s workforce created a solid-state battery to check the fabric, discovering that it held up towards the battery’s calls for. Then, as soon as the battery was handled with an natural solvent, the fabric dissolved—slicing out the need of a shredding step totally.

An outline of batteries made with MIT researchers’ new electrolyte materials, which is constituted of a category of molecules that self-assemble in water, named aramid amphiphiles (AAs), whose chemical constructions and stability mimic Kevlar. [Image: courtesy of the researchers/edited by MIT News]

What’s subsequent

There are a number of shortcomings with the present dissolvable prototype. To begin, Cho says the check battery’s efficiency was properly under that of immediately’s gold-standard industrial batteries.

“The efficiency is at a stage that the trade won’t ever take into consideration—if in case you have an iPhone 13, you’ll by no means take into consideration swapping that for an iPhone 4,” Cho says. “Matching the efficiency to the present state-of-the-art batteries is unquestionably a problem we haven’t demonstrated but.”

A part of that efficiency deficit, Cho says, seemingly comes from the truth that his workforce constructed its battery from the bottom up. Whereas it will likely be a minimum of a number of years earlier than this new materials is perhaps commercially viable, he believes it could possibly be swapped into future EV batteries with out an excessive amount of problem on producers’ elements.

“I feel sooner or later, we will combine this materials as part of the battery,” Cho says. “If you happen to think about that it dissolves like cotton sweet, it might probably simply be a really skinny layer someplace in between the element elements. That may serve the aim of opening the battery in an autonomous means.”